the Creative Commons Attribution 4.0 License.

the Creative Commons Attribution 4.0 License.

The AgraSim (Agricultural Simulator) facility for the comprehensive experimental simulation and analysis of environmental impacts on processes in the soil-plant-atmosphere system

Nicolas Brüggemann

Patrick Chaumet

Normen Hermes

Jan Huwer

Peter Kirchner

Werner Lesmeister

Wilhelm August Mertens

Thomas Pütz

Jörg Wolters

Harry Vereecken

Ghaleb Natour

The AgraSim large-scale research infrastructure is an experimental simulator consisting of six mesocosms (each mesocosm consisting of an integrated climate chamber, plant chamber and lysimeter system) for studying the effects of future climate conditions on plant physiological, biogeochemical, hydrological and atmospheric processes in agroecosystems, which was designed and built by the Forschungszentrum Jülich.

AgraSim makes it possible to simulate the environmental conditions in the mesocosms in a fully controlled manner under different weather and climate conditions ranging from tropical to boreal climate. Moreover, it provides a unique way of imposing future climate conditions which presently cannot be implemented under real-world conditions. It allows monitoring and controlling states and fluxes of a broad range of processes in the soil-plant-atmosphere system. This information can then be used to give input to process-models, to improve process descriptions and to serve as a platform for the development of a digital twin of the soil-plant-atmosphere system.

- Article

(6808 KB) - Full-text XML

-

Supplement

(3442 KB) - BibTeX

- EndNote

Climate change in combination with a steadily growing world population and a simultaneous decrease in agricultural land is one of the greatest global challenges facing mankind (Molotoks et al., 2020). Investigating the effects of the changes in air temperatures and precipitation that have already occurred and are still to be expected in the future on the fundamental processes in agroecosystems, which form the basis for the sustainable management of arable land while maintaining other ecosystem services, such as the recharge of clean groundwater, the storage of carbon and nutrients and the preservation of biodiversity, is of central importance here.

In this context, IBG-3 at Forschungszentrum Jülich decided to establish an “agricultural simulator” (AgraSim), which enables research into the above-mentioned effects of climate change on agricultural ecosystems and the optimization of agricultural cultivation and management strategies with the aid of combined experimental and numerical simulation. ITE is the technology and engineering partner with the task of development and construction of Agrasim.

In its combination of experimental, analytical and simulation capabilities, AgraSim is unique worldwide. By intimately integrating real-time observations and modelling of states and fluxes, a digital twin of the soil-plant-atmosphere system will be created. Understanding the effects of climate change on agricultural yields, the role of the soil for resource use efficiency and the feedback to climate-relevant parameters can be studied and quantified in a way that is unique to date. AgraSim can also be used to test the cultivation of new varieties and their performance under changing climatic conditions. This opens up new opportunities for application-oriented bioeconomic modelling, in particular for the exploration and optimization of new and sustainable cultivation methods.

A comparison of previously implemented ecotrons is described in Roy et al. (2020). In addition, there are other large chamber systems, e.g. by NASA in the USA (Wheeler, 1992), at Kyoto University, Japan (Horie et al., 1995) and at Mendel Agriculture and Forest University in the Czech Republic (Urban et al., 2001), as well as small mobile variants, such as those described in (Leadley and Drake, 1993; Morrow and Crabb, 2000). However, none of these ecotrons compares with Agrasim in terms of complexity and the variety of its features. In addition, the six-fold design of the chambers makes statistical studies possible. The chambers' size also allows for experiments with various agricultural crops, including tall-growing crops such as maize.

The primary aim of the AgraSim research facility is to study how agricultural soils and crops will react to the changing future climate conditions, such as rising temperatures, altered precipitation patterns and increased CO2 concentrations in the atmosphere, and the consequences this will have for yields, soil health and the environment. The fully controllable plant chambers allow various climate scenarios to be simulated in a targeted manner, taking into account all relevant variables: air temperature and relative humidity; atmospheric CO2 concentration; light intensity and spectrum; precipitation; soil temperature with a realistic vertical profile; soil moisture; and the lower hydrological boundary conditions at the bottom of the lysimeter. Key variables of ecosystem matter exchange can also be quantified, including evapotranspiration, net ecosystem exchange of CO2, CH4, N2O, soil water balance, quantity and composition of seepage water, plant growth and performance, and quantity and quality of yield. AgraSim enables the analysis of the nutrient and water use efficiency in the soil-plant-atmosphere system, and the quantification of the feedback of agroecosystems to the atmosphere under future climatic conditions. Stable isotope analysis can be used to disentangle the net fluxes of carbon dioxide, water vapor and nitrogen gases into their component fluxes. This provides the basis for incorporating these processes into model calculations for sustainable agriculture. It is not possible to do this in its entirety in the field, but only in such a sophisticated research facility.

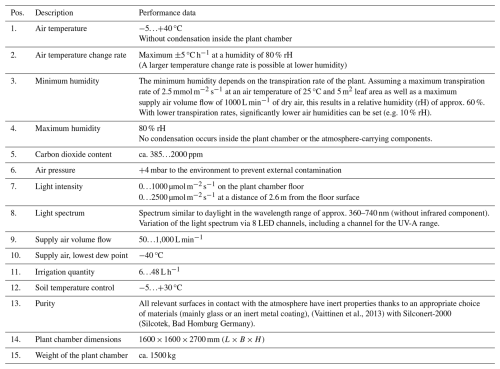

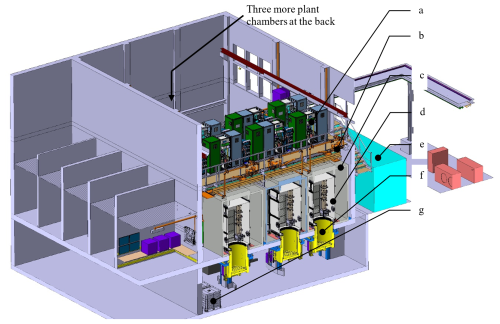

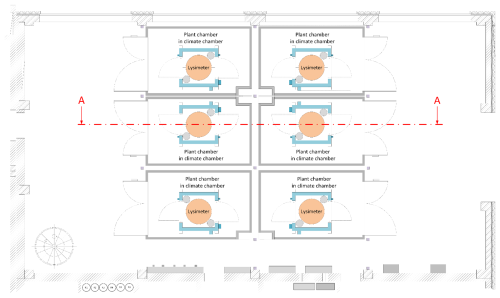

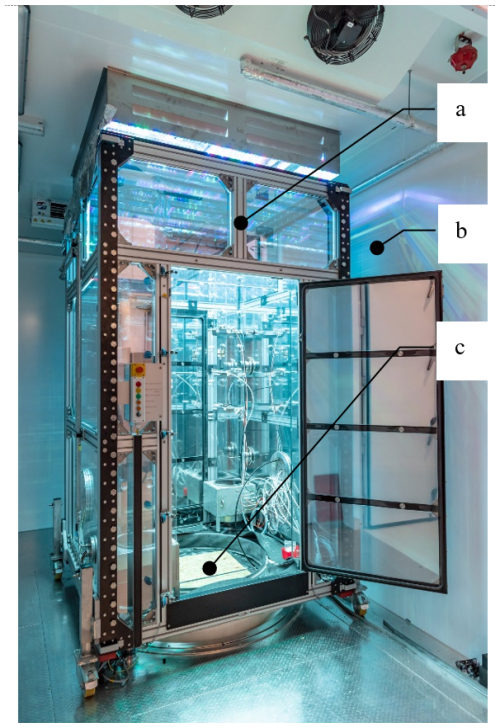

The core of the Agrasim research infrastructure (see Figs. 1 to 3) consists of a total of six plant chambers (Fig. 1d) which can be operated independently of each other. Three chambers can be seen in Fig. 1, three more are located on the opposite side of the hall. The system extends over three floors. On the ground floor the plant chambers are located (Fig. 1d), which in turn are each arranged in a climate chamber (Fig. 1, chamber-in-chamber system). The lysimeter system (lysimeter: soil container) with one lysimeter (Fig. 1f) per plant chamber is located in the basement. The process technology (Fig. 1a), which is used to condition the supply air to the plant chamber, for example, is located on the technical platform on the first floor. The ultra-pure air system (Fig. 1e) for supplying air to the plants is located outside the hall. This produces dry and purified compressed air for the air supply to the plant chambers. The compressed air enters the process technology racks Fig. 1a) on the technology platform, where it is regulated to a defined volume flow, tempered, humidified and mixed with CO2. This conditioned air enters the plant chambers Fig. 1d) and supplies the plants on the lysimeter Fig. 1f) with air. The air is led out of the plant chamber through the exhaust pipe Fig. 1b) and the pressure inside the plant chamber is regulated to a low overpressure (400 Pa). A gas sample of the supply air and a gas sample of the exhaust air from each plant chamber are taken via a valve terminal and sequentially connected to gas analyzers for the determination of water vapor, greenhouse gases (CO2, CH4, N2O) and reactive nitrogen gases (NO, NO2, NH3, HONO). The irrigation station Fig. 1g) in the basement is used to irrigate the surface of the soil in the lysimeters Fig. 1f).

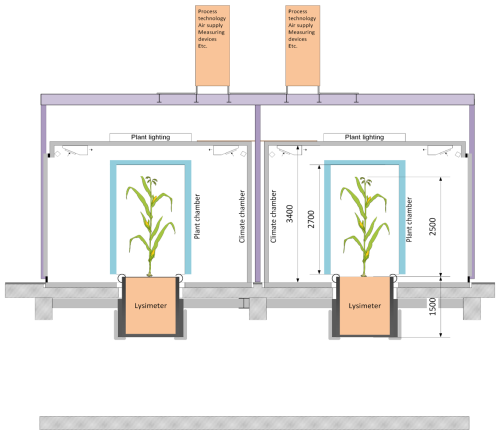

The plant chamber (Fig. 4a) is located inside a climate chamber (Fig. 4b) and is centered and sealed on the lysimeter (Fig. 4c).

The climate chamber (Fig. 4b) supports the temperature control of the plant chamber and prevents condensation inside and outside the plant chamber by ensuring that all external surfaces of the plant chamber, as well as all pipes and hoses, are tempered to the target temperature of the plant chamber by the climate chamber air. The plant lighting is installed in the climate chamber ceiling.

The choice of materials for the construction of the plant chamber and built-in parts is severely restricted, as many materials would change the plant chamber atmosphere through outgassing and/or cause interactions between the plant chamber atmosphere, the soil, the water for irrigation or the plant itself and other materials, which is also undesirable. Some materials, for example, release heavy metals, plasticizers, hydrocarbons or xylene from paints and epoxy adhesives (Knight, 1992) Metallic surfaces made of aluminum, copper, brass, nickel and galvanized zinc can form toxins on contact with nutrient-containing irrigation water (Knight, 1992) (Graves and Adatia, 1983, pp. 103–104). Plastics contain fats, acid and vegetable oil derivatives, which are subject to degradation by microorganisms, as well as ester compounds, phthalic acids, maleic acid and phosphoric acids (Knight, 1992; Mathur, 1974), which are also undesirable in this environment. In addition, some plastics, e.g. polyvinyl chloride (PVC) and polyethylene (PE), contain the plasticizer dibutyl phthalate (DBP), which is toxic to plants at high concentrations (which has already been proven in plant chambers made of plastics) (Knight, 1992). Contact between Plexiglas surfaces and water containing calcium produces gases that are harmful to plants (Mortensen, 1982). Brush motors are another source of hydrocarbons (Knight, 1992).

4.1 Applicable materials

PTFE (polytetrafluoroethylene) and glass are materials that have been shown to have a low impact on the plant's environment (Knight, 1992). O-rings made of Viton or FKM (fluororubber) only release very small amounts of hydrocarbons when exposed to radiation (Knight, 1992). At the same time, O-rings are often concealed and are therefore not irradiated by plant lighting. Furthermore, a surface coating of stainless steel with Silconert-2000 from Silcotek (Bad Homburg, Germany) results in an inert surface (Vaittinen et al., 2013).

4.2 Structure

The outer surfaces of the plant chambers were realized using the following types of glass sheets from the manufacturer Schott (Mainz Germany) and the company Kastenholz (Frechen Germany):

-

Side walls: Laminated safety glass consisting of white glass ESG-H (t = 6 mm), 1.52 mm PVB Interlayer clear UV, white glass ESG-H (t = 8 mm). Mirror foil was applied to the outside of the side walls to reduce the decrease in light intensity over the height (in the lower area with a height of 1 m, the reflectance is 80 %, above a reflectance of 97 % was selected).

-

Floor: Laminated safety glass consisting of 2 × 8 mm white ESG-H glass with 1.52 mm PVB interlayer clear UV

-

Ceiling: ESG-H white glass with Conturan green anti-reflective coating from the manufacturer Schott (Mainz, Germany). This glass has a very low reflectance of 1 %–2 % in the 450–650 nm range. In addition, the transmission is very high at over 97 % in the 450–650 nm range (Schott, 2015, p. 9, p. 12). At shorter and longer wavelengths, the reflectance is higher and the transmission lower, see (Schott, 2015, p. 9, p. 12), which is why this must be compensated for with a higher light intensity.

The plant chamber is sealed using precured, individually manufactured FKM seals (fluororubber, company Flohreus, Veitsbronn Germany). For sealing, all outer edges of the glass panes are pressed against each other with springs with a contact pressure of 3000 N m−1. The heat exchangers (stainless steel 1.4571) and the fan blades (stainless steel 1.4301) arranged in the plant chamber have a large exchange surface with the atmosphere. They were therefore provided with the inert coating Silconert-2000 (Silcotek GmbH, 2023) (vaporization with silicon). These measures lead to very little influence on the atmosphere from the plant chamber and the built-in parts.

The plant lighting can generate up to 3 kW of heat load within the plant chamber. Figure 5 shows the cooling towers used to control the temperature of the plant chamber atmosphere.

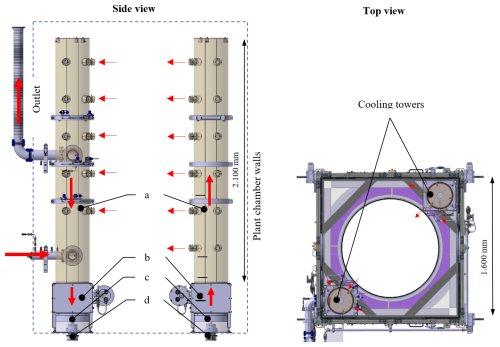

The two cooling towers (Fig. 5) inside the plant chamber are used to control the temperature of the plant chamber atmosphere. In addition to controlling the temperature to the desired value, the cooling towers also ensure homogeneous mixing of the atmosphere.

Each of the two cooling towers consists of a fan (Fig. 5c, Pelzer Ventilatoren, Dortmund, Germany, = 1800 m3 h−1 at Δp = 140 Pa, with Silconert-2000 coating), a heat exchanger arranged above it (Fig. 5b, manufacturer: Schwämmle, type: ELW 4-HP stainless steel, with Silconert-2000 coating) and a mounted air distribution tube made of borosilicate glass (Fig. 5a, Aachener Quarzglas Technologie, Aachen, Germany, and Landgraf Laborsysteme HLL GmbH, Langenhagen, Germany, Ø 300 mm). The flow directions within the two cooling towers are opposite, so that a diagonal flow is created within the plant chamber via the side nozzles of the air distribution pipes. This ensures good mixing of the atmosphere over the entire height of the plant chamber. All components must have a surface temperature above the dew point of the air, including the heat exchangers for cooling. At high humidity, there is therefore only a small ΔT available for cooling the plant chamber atmosphere (e.g., at 75 % rH, the dew point is only 4.7 °C below the air temperature), to ensure that condensation is avoided. However, this low permissible ΔT makes efficient cooling difficult and costly. Therefore, a high air flow rate (approx. 1600 m3 h−1 per cooling tower) and a high cooling water flow rate (approx. 1000 L h−1 per cooling tower) are required to achieve a cooling capacity of approx. 3 kW with such a low ΔT.

At the same time, the air speed should be limited so that the plants are not exposed to too strong air flow, which is why many side nozzles (air speed max 12 m s−1 directly after a side nozzle) were provided in the air distribution pipes (pipe on the left: 15 side nozzles, pipe on the right: 18 side nozzles, Fig. 5). Individual side nozzles can be closed to adapt the flow conditions to the plant. The drive of the fan blades (Fig. 5d) was equipped with a brushless motor and arranged outside the plant chamber. The rotary motion is transmitted into the plant chamber by means of an inert feedthrough. The rotary feedthrough also has a desirable, minimal air purge to the outside of the plant chamber to prevent contamination of the atmosphere by the bearings or the drive itself.

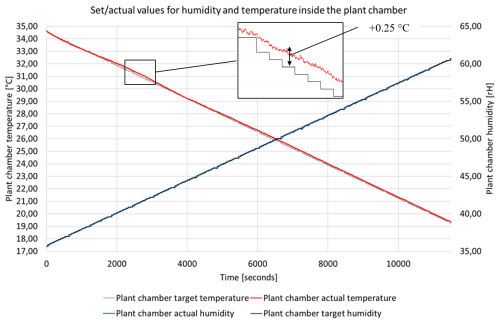

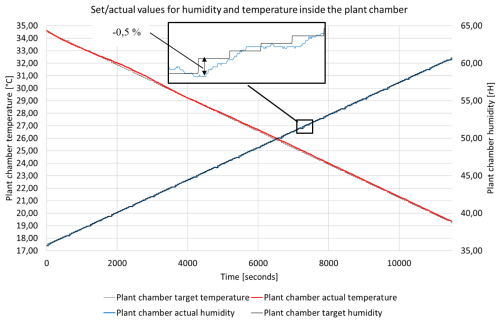

Figure 6 shows the target temperature (black) and the actual temperature (red) inside the plant chamber at maximum plant lighting output over a period of approx. 3 h. The temperature was reduced from 34.5 °C to 19.5 °C. The humidity curve (blue) is also shown (the humidity was also controlled using the profile shown).

-

Temperature sensor: Combined sensor for temperature and humidity

-

Manufacturer/Type: Rotronic/HC2A-SM

-

Control accuracy in this scenario: ±0.25 °C (see Fig. 6)

-

Measurement deviation at 23 °C and ±5 °C: ±0.10 °C

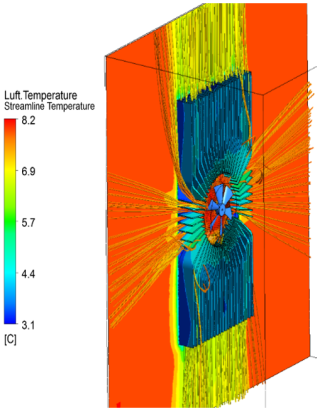

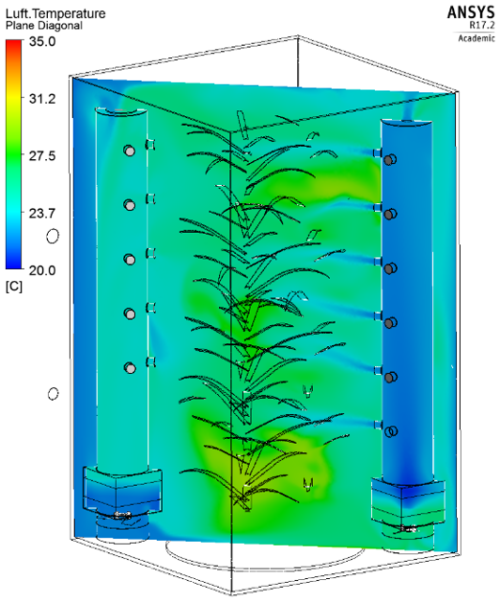

During the development phase, three concepts for controlling the temperature of the plant chamber atmosphere and for dissipating the heat load from the plant lighting (approx. 3 kW) were investigated using CFD (computational fluid dynamics) simulations.

Requirements for the cooling concept:

-

Removal of the heat load introduced by the plant lighting to a maximum of 3 kW with a ΔT between the plant chamber air and the cooling medium of less than 4.7 °C in order to be able to implement an air humidity of 75 % rH without condensation occurring in this extreme scenario. This corresponds to a required cooling capacity of 640 W K−1 ΔT.

-

As space-saving as possible to minimize the impact on the growing space for the plants (diameter: 1129 mm, height: 2500 mm).

-

Use of inert components, especially for components that have a large contact surface with the atmosphere.

The concepts examined were:

- 1.

Cooling via a temperature-controlled plant chamber ceiling

- 2.

Cooling via heat exchangers in the side walls of the plant chamber

- 3.

Implemented and described above: cooling via two cooling towers equipped with heat exchangers and fans

In this concept, the ceiling glass panel of the plant chamber was double-walled, with a cooling liquid flowing through the gap. This allowed the ceiling to be tempered to the desired temperature. A silicone oil was chosen as the cooling medium, which only slightly affects the light spectrum of the plant lighting, even in the UV range. In order to achieve good heat transfer on the inner surface of the plant chamber ceiling, a ceiling fan was provided. The fan blades of which are made of glass and therefore only slightly interfere with the plant lighting. The walls of the plant chamber were also cooled from the outside by the climate chamber air. However, the influence of the climate chamber air on the internal wall temperature of the glass panels was significantly lower than the influence of the tempered ceiling glass panel with plant chamber air flowing against it.

Input variables and boundary conditions for the CFD heat balance simulation:

- –

Ceiling fan data: Ø250 mm | Axial air speed: 10 m s−1

- –

Temperature of ceiling glass panel: 3 °C

- –

Air temperature of climate chamber: 3 °C

- –

The application of the heat load of 3 kW is simplified as follows:

- –

52 % of the energy is absorbed by the floor slab outside the lysimeter (corresponding to the area share).

- –

36 % of the energy is considered as heat flow on the upper sides of the leaves, Reflection of typically 15 % of the radiation is neglected.

- –

12 % of the energy is transferred to the bottom of the lysimeter.

- –

Result of the CFD heat balance simulation

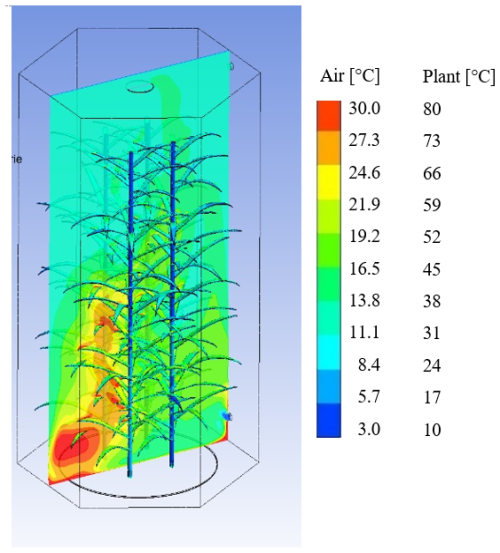

The evaluation showed that the temperature homogeneity was not sufficient if plants are located in the chamber which will prevent even mixing of the cooled air in the whole chamber. High temperatures of up to 30 °C will occur in the lower area of the plant where the air exchange is strongly decreased by the leaves. Moreover, the leaves might suffer from high temperatures due to radiation and in-sufficient cooling. It should be mentioned here that the plant temperatures at the leave-air interfaces shown in Fig. 7 do not consider any heat conduction through the leave or cooling effect due to evaporation and are therefore quite conservative. The main purpose of the modelled plant is to study the influence on the temperature distribution of the air in the chamber. The average air temperature of 15 °C was also clearly too high. For these reasons, this concept was not pursued further.

7.1 Second cooling concept: cooling via heat exchangers in the plant chamber walls

In this concept, a heat sink with a fan was arranged in the side wall of the plant chamber (see Fig. 8). The significantly larger cooling surface of the aluminum plate equipped with ribs was intended to significantly increase the cooling capacity compared to the first concept. In this variant, only the performance of this cooling concept was investigated for an aspired temperature difference of 5 °C between the air in the chamber and the heat sink itself without considering the whole chamber and the influence of plants inside the chamber.

Input variables and boundary conditions for the CFD heat balance simulation:

-

Heat sink dimensions: W = 600 mm | H = 1200 mm | T = 120 mm

-

Cooling fan: Ø250 mm | ca. 1350 m3 h−1

-

Temperature heat sink: 3 °C

-

Air temperature: 8 °C

Result of the CFD heat balance simulation

The cooling capacity for this system is approx. 180 W K−1 of air temperature, or 360 W K−1 if two of these systems are used. The increase in cooling surface area resulted in a significant improvement compared to the first concept, but the cooling capacity was still below the required cooling capacity of 640 W K−1. Moreover, the problem of insufficient mixing of the air within the chamber, especially if plants are located within the chamber, is not solved by this concept. For this reason, this concept was also not pursued further.

In the third concept, the cooling surface was increased once again and the distribution of the air flow in the plant chamber was also improved.

7.2 Third cooling concept: cooling via two cooling towers equipped with heat exchangers and fans

This concept corresponds to the variant described in Sect. 5 and implemented in practice, namely cooling via two cooling towers equipped with heat exchangers and fans.

Input variables and boundary conditions for the CFD heat balance simulation:

-

Air volume flow per fan: 1600 m3 h−1

-

Diameter of the fans: 300 mm

-

Cooling water volume flow per cooling tower: L h−1

-

Cooling water temperature: 20 °C

-

Temperature climatic chamber: 20 °C

Result of the CFD heat balance simulation

The cooling capacity of this system is 655 W K−1 of air temperature, which slightly exceeds the required cooling capacity of 640 W K−1. To dissipate the maximum heat load of 3 kW, it would be sufficient to set an average temperature difference between the cooling water and air of 4.6 °C.

Figure 9 shows that there are limited heat zones in the vicinity of the plant, but these can also be found in plants in nature.

Figure 9Temperature distribution within the plant chamber for the third and then actually realized cooling concept.

This cooling concept was assessed as sufficient and implemented.

Dried and ultra-pure compressed air (manufacturer: HPS, Düren, Germany) is used to supply air to the plant chambers (residual particles down to 0.01 µm with a separation efficiency of 99.9999 %, dew point: −40 °C, manufacturer of the compressed air fine filters and activated carbon filters: Parker, Bielefeld, Germany). The compressor type is a water-injected oil-free screw compressor for generating oil-free compressed air (manufacturer: compare, Simmern, Germany) in a fully redundant design.

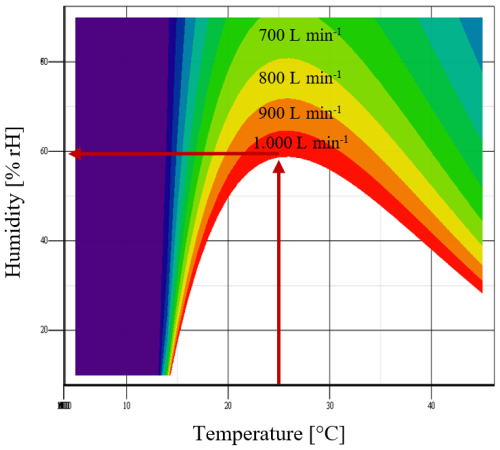

The supply air volume flow is adjusted to the requirements of the experiment and the plant per plant chamber (50…1000 L min−1). After compressed air generation and volume flow regulation, the compressed air is pre-tempered by a heat exchanger to a temperature similar to the desired plant chamber temperature.

The diagram in Fig. 10 shows the calculation result for the required supply air volume flow of dry supply air (dew point −40 °C) for drying the plant chamber atmosphere at the maximum transpiration rate of the plant (transpiration rate at 25 °C and 5 m2 leaf area: 2.5 mmol m−2 s−1, corresponds to 0.45 g H2O s−1).

Figure 10Required supply air volume flow to keep the humidity constant depending on the plant chamber temperature.

Example: A volume flow of 1000 L min−1 is required to keep the humidity constant at approx. 60 % rH at 25 °C (Fig. 10).

To humidify the supply air of the plant chamber, demineralized water (electrical conductivity κ ≤ 0.1 µS cm−1, concentration of active silicic acid (SiO2): < 0.02 mg L−1, no chloride ions) is heated together with a small amount of compressed air (5 L min−1) in an evaporator (manufacturer: Institut für Chemische Verfahrenstechnik, Stuttgart, Germany) to form a water vapor-air mixture and fed into the supply air. The mixture then passes through a static impeller mixer for homogenization (supplier: Institut für Chemische Verfahrenstechnik, Stuttgart, Germany). To prevent condensation, all components from the evaporator onwards are heated by a pipe heating system (type: FG200, Wagner GmbH, Wülfrath, Germany). To enable humidity control even at temperatures below freezing, an additional heater ensures that the supply air is at least +3 °C before humidification. The humidified air is mixed with the plant chamber atmosphere inside the plant chamber and cooled there by the cooling towers to the desired temperature, taking the dew point into account. This also enables humidity control at temperatures below the freezing point up to 80 % rH.

In the test shown in Fig. 11, the humidity was increased from 19.5 % to 61 % over a period of approx. 3 h, while the temperature was reduced from 34.5 to 19 °C during this period.

-

Humidity sensor: Combined sensor for humidity and temperature

-

Manufacturer/Type: Rotronic/HC2A-SM

-

Measurement deviation at 23 °C and ±5 °C: ±0.8 % rH

-

Control accuracy in this scenario: ±0.5 % rH (see Fig. 11)

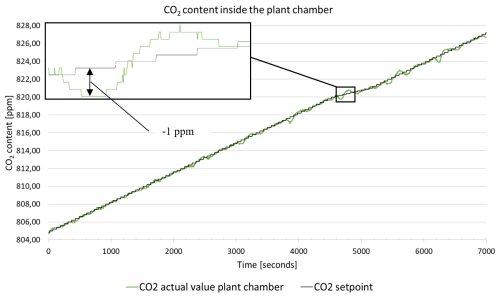

For CO2 control within the plant chamber, CO2 (purity grade 4.5 | 99.995 %) is dosed into the supply air using two mass flow controllers (type: EL-FLOW Select, Bronk-horst, Kamen, Germany), mixed with the supply air using a static impeller mixer (Institut für Chemische Verfahrenstechnik, Stuttgart, Germany) and then this mixture is fed into the plant chamber. The CO2 content is measured both in the supply air and in the plant chamber (type see below) in order to regulate the CO2 content in the plant chamber and to quantify the influence of the plant on the atmosphere of the plant chamber and the CO2 uptake/release of the plants.

Figure 12 shows the control accuracy for CO2. An increase in the CO2 content from 805 to 827 ppm was specified over a period of approx. 2 h, whereby significantly larger increases are also possible.

-

CO2 Measuring device: Manufacturer Emerson, Langenfeld, Germany

-

Type: X-STREAM (XEPG)

-

Measurement deviation ≤ ±15 ppm

-

Control accuracy: ±1 ppm (see Fig. 12)

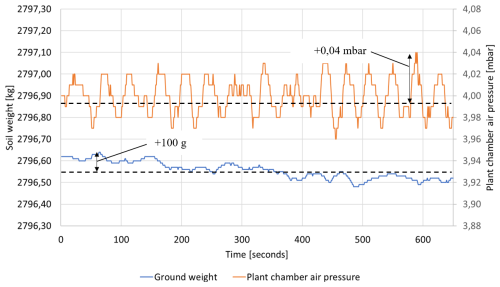

The plant chamber is kept under a slight overpressure of 400 Pa to prevent external contamination. The plant chamber pressure must be controlled very precisely (see Fig. 13 for control accuracy), as the pressure increase over the surface of the lysimeter results in an apparent additional weight on the soil scale. Weighing provides important information about the water balance in the soil. The lysimeter weight can be used to determine the evapotranspiration, the exact irrigation rate, which is a very important parameter. The measurement accuracy of this weight measurement without the influence of air pressure is ±50 g (with a mass of the lysimeter including soil of approx. 2.8 t). A pressure fluctuation of ±100 Pa in the plant chamber would result in a weight fluctuation of ±10 kg due to the lysimeter surface area of 1 m2, which would make the weight measurement and the resulting irrigation quantity unusable. For this reason, it is essential to regulate and measure the air pressure very precisely as shown in the following table:

Pressure measurement/control:

-

Sensor type: Differential pressure sensor 266MST

-

Manufacturer: ABB, Ratingen, Germany

-

Sensor measurement deviation: ±0.4 Pa

-

Control accuracy: ±4 Pa (see Fig. 13)

The remaining influence of this small pressure fluctuation (±4 Pa = ±400 g fluctuation of the soil weight) is offset against the measured value of the lysimeter weight, which further increases the accuracy of the weight determination.

The diagram Fig. 13 shows the measured plant chamber air pressure and the soil weight over a period of approx. 10 min.

Wight measurement:

-

Sensor type: 3 x load cell for a load of 1000 kg each

-

Supplier: JR-Aquaconsol, Graz, Austria

-

Measurement deviation: ±50 g

-

Measuring accuracy due to the pressure control and taking into account the differential pressure measurement between the plant chamber and the environment: ±100 g (see Fig. 13)

The water for irrigation is produced from demineralized water, minerals and other additives according to the user's specifications in a 1000 L tank. The water is supplied via pumps (gear pump | manufacturer Iwaki, Willich, Germany | type MDG) and a drip hose (Kärcher, Winnenden, Germany | type: Ø1/2′′) based on the specified climate data and is evenly distributed over the soil surface. The irrigation components (such as the hose, the flow meter and the drip hose) are regularly flushed with air to ensure that the irrigation volume is applied as precisely as possible and to prevent standing water from freezing in the hoses at temperatures below the freezing point (at temperatures below freezing point, irrigation no longer takes place). The watering volume can be set between 6 and 48 L evenly distributed over a time of 1 h.

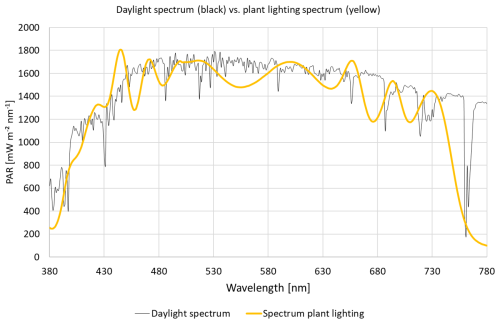

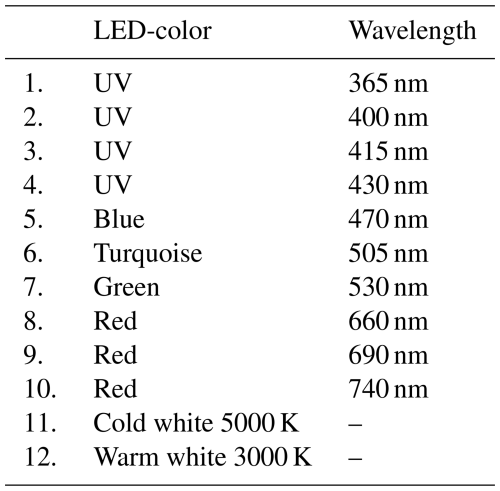

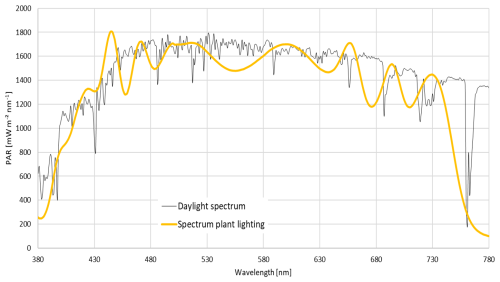

With the plant lighting (manufacturer: Roschwege, Greifenstein, Germany), individual spectra similar to daylight (see Fig. 14 for an exemplary spectrum) can be displayed using 12 different LED types (see Table 2). The maximum brightness is 2500 µmol photons m−2 s−1) at a distance of 900 mm from the plant lighting.

The lysimeter system used for Agrasim is based on the technical concept established in TERENO-SOILCan (Pütz et al., 2016). The lysimeters are stainless steel containers with a surface area of 1 m2, a depth of 1.5 m and are filled with a soil monolith. To control the hydraulic properties of the lysimeter, the lower boundary condition is set to the desired values using a suction cup rake in combination with a bidirectional pump, a precision tensiometer and a high-precision weighable stainless-steel container with a volume of 100 L to collect the percolate. Water is either pumped into or out of the lower region of the lysimeter. The lysimeters are installed hanging from the cellar ceiling. The high-precision weighing system of a lysimeter consisting of three load cells (model 3510, JR-Aquaconsol, Graz, Austria) and the associated percolate container allow the exact recording of the various measured variables of the water balance equation, such as evapotranspiration, precipitation, dew, percolate and water content change of the soil. In addition, sensors for measuring soil temperature and soil moisture (tensiometer TEROS-41) and TDR-Sensors (Campbell Scientific, Santa Clara, USA), soil potential sensors (CS650, TEROS-21), temperature profile sensors (TH3-S, JR-Aquaconsol) are located at various depths in the lysimeter. The soil solution is sampled using suction cups and a control unit (JR-Aquaconsol). For chemical analysis the percolate is sampled from the downward water flow via an aliquoting unit. The soil temperature is controlled via a heat exchanger loop (JR-Aquaconsol) installed in the lower area of the soil.

An additional system will be used to take gas samples from six depths of the soil from each lysimeter for isotope analysis with a gas analyzer from the company Picarro (Logan, USA). For this purpose, six microporous hoses (outer diameter: 9 mm) are inserted horizontally at different depths (5, 10, 20, 40, 80, 120 cm from the lysimeter upper edge) into the lysimeter through boreholes. Synthetic air (0.5 L min−1) is passed through the microporous hoses as a transport gas. Gaseous substances from the soil can pass through the shell of the microporous hoses and are transferred to the transport gas in the hoses. A total of six lysimeters are sampled in this way, which means that with six samples per lysimeter, a total of 36 gas samples are sequentially switched to the gas analyzer via valves and hose lines. From the outlet of the microporous hose at the lysimeter, the entire hose and valve section must be heated to prevent condensation on the gas-carrying surfaces. In addition, the humidity of the sample can be regulated to the optimum humidity value for the gas analyzer by adding a specific amount of synthetic air before transferring it to the gas analyzer.

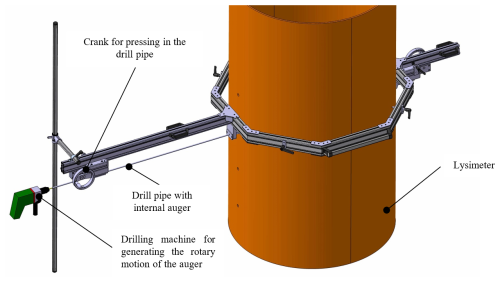

The boreholes for the microporous hoses must run precisely through the ground. A specially developed drilling rig is used for this purpose (see Fig. 15). It can be aligned and fixed at the lysimeter shell with the aid of cylindrical mounts in the start and target boreholes. With this drilling rig, a drill pipe is pressed into the soil, in which an auger runs and protrudes approx. 20 mm at the end of the drill pipe. The auger loosens the soil in front of the drill pipe and partially removes it so that the drill pipe can be pressed into the ground with less force and the impact on the surrounding soil is small. However, only a fine-grained part of the soil can be removed with the auger, which leads to an unavoidable slight compaction of the soil. Once the borehole has been drilled, the microporous tube is pulled in backwards using the drill pipe.

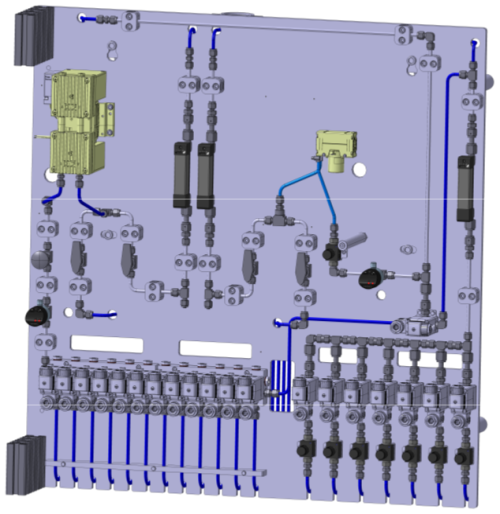

For the scientific gas analysis of the atmosphere of the plant chambers, one gas sample is taken from the supply air and one gas sample from the exhaust air from each of the six plant chambers. The gas samples are transported at a negative relative pressure of −40 kPa in order to avoid condensation within the transport hoses. The negative pressure must be maintained in all twelve transport lines at all times, which is continuously assured by one of two vacuum pumps. Each of these twelve gas samples is switched to isotope gas analysers via 3/2-way valves and analysed. A second vacuum pump also ensures that the negative pressure is maintained for the gas sample which is switched on the gas measuring device. A filter and an orifice (orifice diameter: 10 µm, heated) are located at the inlet of each transport tube to generate the negative pressure. A volume flow of 0.5 L min−1 (based on 20 °C and 1013 mbar) is required per transport hose in order to generate a negative pressure difference of −40 kPa via this orifice. In addition, reference gases can be switched per 2/2-way valves to the gas measuring device for calibration. Figure 16 shows the corresponding valve terminal.

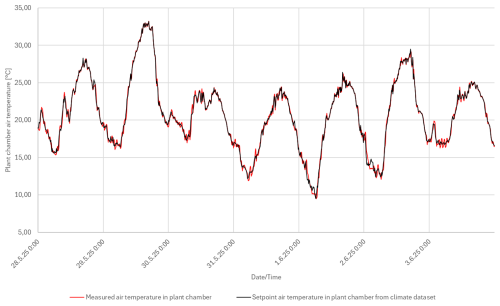

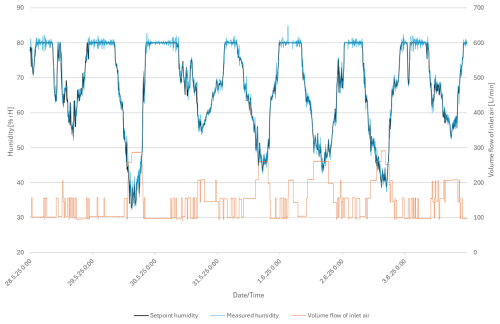

To evaluate the performance of the control system with regard to environmental parameters such as temperature, humidity, etc., the relevant data was analyzed in an experiment with forage peas (Pisum sativum).

The experiment represented a realistic case. The climate defaults used were based on a real recorded climate dataset, simulating dynamic, practice-relevant fluctuations in light, temperature, humidity, etc. with a time resolution of 1 min. In addition, the influence of rapid changes in environmental conditions (e.g. sudden changes in light intensity) on the control strategy is documented, particularly with regard to its reaction time. The focus is on the differences between actual and setpoint values, and their evaluation in the context of the system's operating strategy.

Parameters of the experiment

-

Operating mode. The system was in regular automatic mode.

-

Plant population. 120 plants of the species Pisum sativum (forage peas) were cultivated on each lysimeter with an area of 1 m2.

-

Plant development. At the time of this evaluation, the plants had an average height of 41 cm and a Leaf Area Index (LAI) of 1.965.

-

Period of review for this evaluation.

- -

Start: 28 May 2025 00:00

- -

End: 4 June 2025 23:59

- -

Duration: 7 d

- -

-

Climate control.

- -

The basis was a real, measured climate dataset from 2017 (see the respective curves of the target values in the following diagrams).

- -

New setpoint values for the relevant climate parameters were specified for the system every minute.

- -

The control of the CO2 concentration of the chamber air was switched off, as the diurnal fluctuating CO2 concentration of the outside air was used in this experiment.

- -

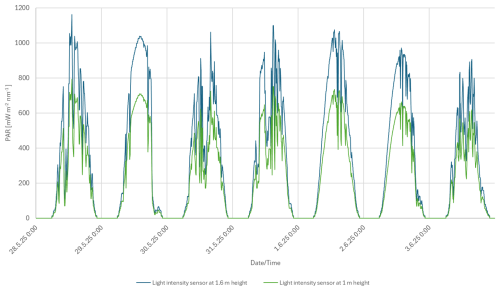

17.1 Evaluation of the light intensity over time

Figure 17 shows the progression of photosynthetically active radiation (PAR) measured by two PAR sensors at different heights (1 and 1.6 m above the soil surface). The light spectrum was kept constant over the entire duration of the test and is shown in Fig. 18.

Figure 17Intensity of photosynthetically active radiation (PAR) over the 7 d experimental period, measured at two different heights in the plant chamber (1 and 1.6 m above the soil surface).

17.2 Evaluation of the plant chamber temperature

Figure 19 shows the course of the target and actual temperature in the plant chamber over the experiment duration of 7 d.

Analysis of the temperature deviation between actual and setpoint value

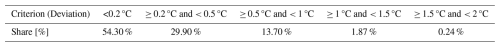

Table 3 shows the percentage distribution of deviations between the measured (actual) and the specified (target) air temperature over the test period (7 d).

Table 3Frequency and magnitude of the deviation of the actual chamber air temperature from the setpoint value.

The evaluation shows that the system was able to control the air temperature with a deviation of less than ±0.5 °C more than 84 % of the time (sum of the first two classes). Larger deviations occurred only for short periods of time (15.81 % of the time) – particularly in the case of rapid changes in light intensity, as prescribed by the climate dataset. In such cases, the system requires a certain reaction time to follow the new external setpoint and restore the correct climatic conditions in the chamber.

17.3 Evaluation of the plant chamber humidity

The following diagram in Fig. 20 shows the course of the target and actual relative humidity in the plant chamber over the experiment duration of 7 d. The supply air volume flow (orange curve, right axis) of the plant chamber is also shown.

Analysis of the deviation between target and actual relative humidity

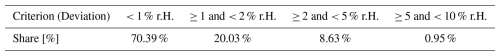

Table 4 shows the percentage distribution of deviations between the specified (target) and the actual relative humidity over the 7 d test period.

Table 4Frequency and magnitude of the deviation of the actual chamber air relative humidity from the setpoint value.

In over 90 % of the time (sum of the first two classes), the system was able to control the relative humidity with a deviation of less than ±2 % relative humidity. Larger deviations occurred only for short periods of time (sum of the last two classes: in total less than 10 % of the time). This is mainly due to the fact that the control strategy has an additional objective: to maintain a constant supply air volume flow – a key control variable in relative humidity control – for as long as possible. Therefore, adjustments to the volume flow are only made in 50 L min−1 increments and only when necessary. This additional control priority is crucial for the gas analysis, which measures differences between the supply and exhaust air of the chamber. To obtain reliable measurement results, the flow rate must be as constant as possible. Therefore, the control system deliberately allows for minor, short-term deviations in relative humidity as long as the existing supply airflow is sufficient.

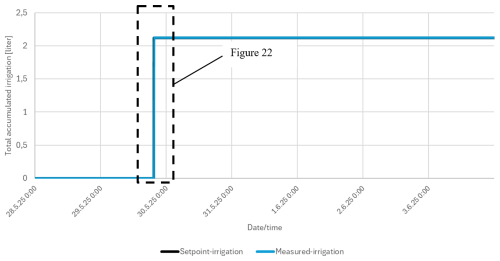

17.4 Irrigation

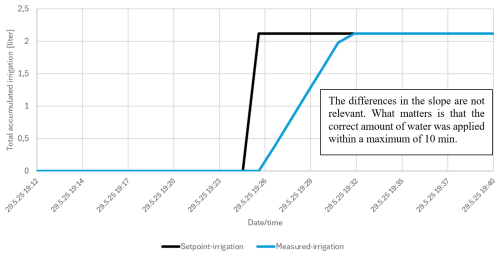

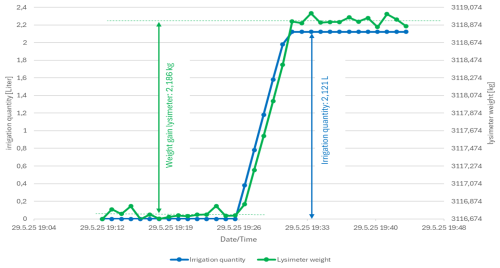

Figure 21 shows the comparison between the setpoint for the irrigation quantity and the corresponding measured value of the flow meter. The two curves are so close to each other that a distinction is only possible in the detailed view (see Fig. 22).

Analysis of the deviation between target and measured irrigation quantity:

-

Target irrigation quantity: 2.12 L

-

Measured irrigation quantity: 2.121 L

-

Deviation: 0.001 L or 0.047 %

Once irrigation is complete, compressed air is used to flush the tubing behind the flow meter to ensure that the entire volume of water is transported to the lysimeter. The evaluation of the lysimeter weight in the following chapter shows that a corresponding increase in weight was recorded at the time of irrigation, which confirms the successful application of water.

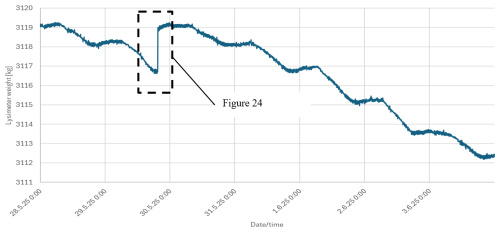

17.5 Analysis of the lysimeter weight

Figure 23 shows the development of the lysimeter weight over time. At the time of irrigation (29 May 2025, 19:26), a clear increase in weight can be seen, which confirms the successful input of water into the lysimeter. This is followed by a continuous decrease in weight, which can be attributed to evapotranspiration – i.e. soil evaporation and plant transpiration. A pronounced day-night dynamic was observed: the decrease in weight was significantly greater during the day than the small gain at night. This effect correlates with the varying light intensity and higher temperatures during the day (see Figs. 17 and 19).

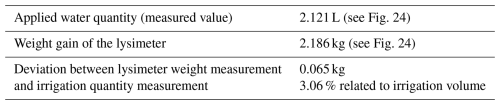

The weight change of the lysimeter corresponded well with the applied amount of water (Fig. 24).

Figure 24Comparison of the weight increase of the lysimeter at the time of irrigation the measured amount of water applied.

17.6 Soil temperature

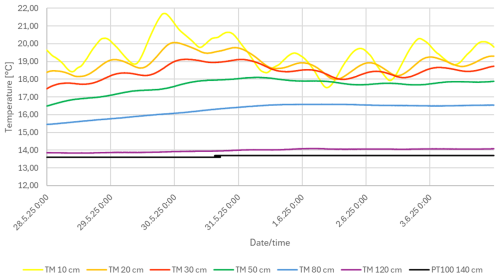

Figure 25 shows the soil temperature readings of the tensiometers (TM) at different soil depths. The following observations can be derived from the data:

-

The measured values of the two tensiometers close to the surface (TM10 and TM20, i.e., at depths of 10 and 20 cm, respectively) showed pronounced daily fluctuations that correlate with the air temperature. These fluctuations decreased significantly with increasing soil depth.

-

The soil temperature at the lower end of the lysimeter was actively maintained constant at 13 °C by means of a heat exchanger loop in the soil. Accordingly, both the deepest tensiometer (at a depth of 120 cm) and the PT100 temperature sensor at a depth of 140 cm measure almost constant temperatures of around 13 °C in this area.

-

Overall, there was a vertical temperature gradient within the lysimeter: while the upper soil layers were strongly influenced by the fluctuating air temperature, the heat exchanger loop at the bottom of the lysimeter ensured a stable thermal boundary condition in the lower area.

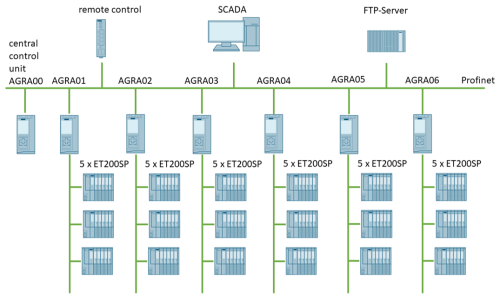

Programmable logic controllers (PLCs) from the Siemens SIMATIC S7-1500 family are used to control AgraSim (Control system layout, see Fig. 26). Each of the six AgraSim systems has its own CPU, which ensures the independence of the individual chambers. Furthermore, an additional PLC controls and monitors all infrastructure systems, such as the central gas supply, the central chillers, the compressed air system and the demineralized water treatment (fully desalinated water). The individual chambers can obtain the necessary information from the central control system via a facility-wide IP network and communicate with other control systems in the facility. For example, data is also exchanged with the climate chamber control system, the plant lighting and the lysimeter system. Remote access via VPN server (Virtual Private Network) was implemented via the plant network and a GSM router (Global System for Mobile Communications), which allows various manufacturers of components (e.g. the climate chambers) to gain access to their control system for service purposes without having access to the control systems of other manufacturers.

Where possible, the process sensors and actuators are connected to the control system in a decentral manner. This reduces the cabling effort to a minimum and the available installation space can be optimally utilized. By using the IO system of the Siemens SIMATIC ET200SP family, the desired modularity and flexibility of the control system was achieved. Various bus systems are used for communication with the sensors/actuators, e.g., Profinet, Profibus, RS232, Modbus RTU and SDI-12 bus. The system is visualized, fully operated and monitored via a central master computer in a control room.

The plant chamber atmosphere follows the previously defined default values, such as air temperature, humidity, etc. from climate data profiles. The climate data profiles are based on measurements taken in the field or self-generated data profiles. These profiles cover at least a full year. FTP (File Transfer Protocol) is used as the data protocol in the facility's network to provide the climate data profiles and store all measured values. A separate FTP-server is therefore installed in the network. The control system uses the specified climate data to calculate the set values for the corresponding actuators for precise control of the environmental conditions.

As SCADA system (Supervisory Control and Data Acquisition) Siemens SIMATIC WinCC Professional is used. Visualization was implemented using multi-monitor operation (four 32′′ monitors). Other SCADA functions include user administration with different operating rights, language switching, event recording, a notification function and measurement data acquisition. Using the Alarm Control Center from Alarm IT Factory GmbH, the events from the SCADA system are transferred to an app for mobile devices. In this way, the system informs the operator about the status of the facility while he is not present.

A prototype was initially built, on which the overall concept, all controllers, sensors and measuring devices were tested. Over 50 000 purchased and manufactured parts were processed for the further construction of the entire system AgraSIM. All components were managed in a database, the order and production statuses were documented and the components were finally sorted and commissioned according to assembly and component ID. The CAD model of the entire system served as the basis for assembly.

It is foreseen to run experiments over several years, including growth and dormant period of the plants. The Maintenance work is specifically scheduled for a period outside the growth period, e.g. after crop harvest. The maintenance work is bundled in order to keep downtimes of the facility as short as possible.

Breakdowns:

-

In general, the persons responsible for the system are notified at an early stage via a cell phone app in the event of slightly deviating control values, i.e. before a system failure, in order to prevent a system failure as far as possible.

-

In the event of a system failure, the maintenance personnel are informed immediately via a cell phone app to enable rapid recovery.

-

In the event of a system failure, the impact on the experiment, depending on the length of the system failure, must be checked individually.

-

The same experiment can be run several times in parallel in different plant chambers.

The AgraSim large-scale research infrastructure is an experimental simulator consisting of six mesocosms (each mesocosm consisting of an integrated climate chamber-plant chamber and lysimeter system) for studying the effects of future climate conditions on plant physiological, biogeochemical, hydrological and atmospheric processes in agroecosystems, which was designed and built by the Forschungszentrum Jülich.

AgraSim makes it possible to simulate the environmental conditions in the mesocosms in a fully controlled manner under different weather and climate conditions ranging from tropical to boreal climate. Moreover, it provides a unique way of imposing future climate conditions which presently cannot be implemented under real-world conditions. It allows monitoring and controlling states and fluxes of a broad range of processes in the soil-plant-atmosphere system. This information can then be used to give input to process models, to improve process descriptions and to serve as a platform for the development of a digital twin of the soil-plant-atmosphere system.

Each mesocosm consists of a temperature-controlled and weighable soil lysimeter unit with intact soil columns (1 m2 surface area and 1.5 m depth) and a transparent, fully controllable plant chamber within a temperature-controlled climate chamber with an LED light source that can provide light in the wavelength range of 360–740 nm very similar to the natural solar spectrum with a maximum intensity of 2500 µmol of photosynthetically active photons m−2 s−1. With an in-house developed, fully automated process control system, defined climatic and weather conditions as well as air compositions can be set and either kept constant over longer periods of time or varied on the basis of a predefined weather data profile. The implementation involves a considerable amount of in-house development by the Central Institute of Engineering, Electronics and Analytics (ITE) in close cooperation with the Institute of Bio- and Geosciences – Agrosphere (IBG-3) at Forschungszentrum Jülich as well as other institutes and external collaborators, as comparable measuring platforms and experimental simulators do not yet exist.

High demands are placed on the plant chamber and the process technology. The inner surfaces of the plant chambers have the purest and most inert properties possible, with the aim of minimizing interactions between the ambient air of the plants and the chamber wall. Strong LED-based plant lighting provides light conditions similar to daylight, which prevents too large heat input into the chamber. A new concept was developed and implemented to dissipate this heat, which is described in this publication. An important point to consider in the development was to avoid condensation at all times, as condensation dissolves gas molecules from the air in the condensate, changing the isotope composition and thus impeding the atmospheric measurements.

The tasks for the process technology to control the entire system are extensive and varied, which is why an individual, customized solution had to be developed for this purpose. These include precise control of the supply air volume flow, pressure, humidity, CO2 content, air temperature, light intensity within the plant chamber, soil temperature and irrigation.

The AgraSim facility is currently in the start-up phase. The soil planned for the future experiments is then selected and placed in the lysimeters. The soil will be excavated with the lysimeters in order to preserve the natural soil structure. Once the lysimeters have been installed in the system, the first experiments will be started.

Each plant chamber is also already prepared for the addition of ozone gas exposure. This would also allow the test plants to be exposed to an increased ozone concentration. However, this system has not yet been implemented. It can be added at a later stage.

The concept described can also be implemented with significant modifications. For example:

-

Adapted dimensions and shapes of the atmosphere chamber (plant chamber).

-

Adapted air supply, e.g. by mixing the air with various pure gases, adding volatile organic compounds (VOCs), fine particles or similar.

-

Adapted pressure conditions, e.g. use of a lower pressure in the chamber.

-

Use of other sensor systems to examine the plant and integration of these sensors into the facility control.

-

Adapted light spectrum and brightness.

By adapting the concept to the user's requirements, completely different applications are also conceivable, such as the “Cactus” system also planned by ITE and ICE-3 at Forschungszentrum Jülich. The system provides a defined atmosphere in a small chamber (Ø200 mm, length 1500 mm) in order to calibrate gas sensors under a variety of conditions. The chamber air is composed of several pure gases, humidified, mixed with volatile organic compounds (VOCs) and fine particles and tempered. Both positive and negative pressure can be set. The chamber itself is inert and clean due to the Silconert-2000 coating.

It would also be conceivable to use AI (artificial intelligence) to evaluate the test data, e.g. to analyze correlations and dependencies. AI could also be an auxiliary tool for controlling the measured variables (e.g., CO2, temperature) by using AI to determine the optimum control parameters for each measured variable and the current scenario.

The supplement related to this article is available online at https://doi.org/10.5194/gi-14-353-2025-supplement.

The large-scale experiment Agrasim was developed and the construction supervised by the entire team. Project management was the responsibility of JN on the technical side and NB and TP on the scientific side. Simulations and calculations were carried out by JW. The mechanical construction was performed by JH and WM. The electrical planning was implemented by PK and PC, the design and development of the control system was the responsibility of PC. WL was significantly involved in the assembly of the experiment. NH supervises the system in experimental operation and contributed to the development and construction. As institute directors, NG and HV laid the foundations for the development, construction and operation of such a large-scale experiment. The paper was conceived and written by JN, NB, PC, NH, JH, PK, WL, WM, TP, JW, HV and GN.

The contact author has declared that none of the authors has any competing interests.

Publisher’s note: Copernicus Publications remains neutral with regard to jurisdictional claims made in the text, published maps, institutional affiliations, or any other geographical representation in this paper. While Copernicus Publications makes every effort to include appropriate place names, the final responsibility lies with the authors. Also, please note that this paper has not received English language copy-editing. Views expressed in the text are those of the authors and do not necessarily reflect the views of the publisher.

We thank the Helmholtz Association for providing funding for Agrasim within the program “Changing Earth – Sustaining our Future” of the research field Earth and Environment.

Finally, I would like to thank the main workshop of ITE for their technical support and professional service. Thanks to the main workshop. All equipment, materials and components were provided and installed on time and in perfect condition.

This research has been supported by the Bundesministerium für Bildung und Forschung (grant no. TERENO-MED).

The article processing charges for this open-access publication were covered by the Forschungszentrum Jülich.

This paper was edited by Jean Dumoulin and reviewed by two anonymous referees.

Graves, C. and Adatia, M.: Nickel toxicity in nutrient film culture, annual report. Glasshouse Crops Res. Inst., 103–104, 1983.

Horie, T., Nakagawa, H., Nakano, J., Hamotani, K., and Kim, H. Y.: Temperature gradient chambers for research on global environment change. III. A system designed for rice in Kyoto, Japan, Plant Cell Environ., 18, 1064–1069, https://doi.org/10.1111/j.1365-3040.1995.tb00618.x, 1995.

Knight, S. L.: Constructing Specialized Plant Growth Chambers for Gas-exchange Research: Considerations and Concerns, HortScience, 27, 767–769, https://doi.org/10.21273/HORTSCI.27.7.767, 1992.

Leadley, P. W. and Drake, B. G.: Open top chambers for exposing plant canopies to elevated CO2 concentration and for measuring net gas exchange, Vegetatio, 104, 3–15, https://doi.org/10.1007/BF00048141, 1993.

Mathur, S. P.: Phthalate Esters in the Environment: Pollutants or Natural Products, J. Environ. Qual., 3, 189–197, https://doi.org/10.2134/jeq1974.00472425000300030001x, 1974.

Molotoks, A., Smith, P., and Dawson, T. P.: Impacts of land use, population, and climate change on global food security, Food Energy Secur., 10, e261, https://doi.org/10.1002/fes3.261, 2020.

Morrow, R. C. and Crabb, T. M.: Biomass Production System (BPS) plant growth unit, Adv. Space Res., 26, 289-298, https://doi.org/10.1016/S0273-1177(99)00573-6, 2000.

Mortensen, L.: Growth responses of some greenhouse plants to environment. III. Design and function of a growth chamber prototype, Scientia Horticulturae, 16, 57–63, https://doi.org/10.1016/0304-4238(82)90024-3, 1982.

Pütz, Th., Kiese, R., Wollschläger, U., Groh, J., Rupp, H., Zacharias, S., Priesack, E., Gerke, H. H., Gasche, R., Bens, O., Borg, E., Baessler C., Kaiser, K., Herbrich, M., Munch, J.-C., Sommer, M., Vogel, H.-J., Vanderborght, J., and Vereecken, H.: TERENO-SOILCan: a lysimeter-network in Germany observing soil processes and plant diversity influenced by climate change, Environ. Earth Sci., 75, 1242, https://doi.org/10.1007/s12665-016-6031-5, 2016.

Roy, J., Rineau, F., De Boeck, H. J., Nijs, I., Pütz, T., Abiven S., Arnone III, J. A., Barton, C. V. M., Beenaerts, N., Brüggemann, N., Dainese, M., Domisch, T., Eisenhauer, N., Garré, S., Gebler, A., Ghirardo, A., Jasoni, R. L., Kowalchuk, G., Landais, D., Larsen, S. H., Leemans, V., Le Galliard, J., Longdoz, B., Massol, F., Mikkelsen, T. N., Niedrist, G., Piel, C., Ravel, O., Sauze, J., Schmidt, A., Schnitzler, J., Teixeira, L. H., Tjoelker, M. G., Weisser, W. W., Winkler, B., and Milcu, A.: Ecotrons: Powerful and versatile ecosystem analysers for ecology, agronomy and environmental science, Glob. Change Biol., 27, 1387–1407, https://doi.org/10.1111/gcb.15471, 2020.

Schott: Spezifikation PCE Physikalische und chemische Eigenschaften Conturan, p. 9, 12, 2015.

Silcotek GmbH: The ultimate inert coating for improved sampling and trace-level analysis of active compounds, https://silcotek.de/wp-content/uploads/2017/10/SilcoNert2000-Data-Sheet_4-8-2016_DE.pdf(last access: 21 November 2025), 2023.

Urban, O., Janouš, D., Pokorný, R., Markova, I., Pavelka, M., Fojtík, Z., Šprtová, M., Kalina, J., and Marek, M. V.: Glass Domes with Adjustable Windows: A Novel Technique for Exposing Juvenile Forest Stands to Elevated CO2 Concentration, Photosynthetica, 39, 395–401, https://doi.org/10.1023/A:1015134427592, 2001.

Vaittinen, O., Metsälä, M., Persijn, S., Vainio, M., and Halonen, L.: Adsorption of ammonia on treated stainless steel and polymer surfaces, Appl. Phys. B, 115, 185–196, https://doi.org/10.1007/s00340-013-5590-3, 2013.

Wheeler, R. M.: Gas-exchange measurements using a large, closed plant growth chamber, National Center for Biotechnology Information (NCBI), https://journals.ashs.org/view/journals/hortsci/27/7/article-p777.xml (last access: 21 November 2025), 1992.

- Abstract

- Introduction

- Performance of the system

- Structure and function of the system

- Plant chamber

- Temperature control of the plant chamber atmosphere via two cooling towers

- Concepts investigated for temperature control of the plant chamber atmosphere

- First cooling concept: Cooling via the plant chamber ceiling

- Preparation of supply air

- Humidification

- CO2 addition

- Air pressure control

- Irrigation

- Plant lighting

- Lysimeter system

- Gas sampling of lysimeters

- Gas sampling plant chambers

- Evaluation of the control quality and measurement accuracy of an experiment with forage peas

- Control system of AgraSim

- Assembly of the experiment

- Maintenance

- Summary

- Outlook

- Author contributions

- Competing interests

- Disclaimer

- Acknowledgements

- Financial support

- Review statement

- References

- Supplement

- Abstract

- Introduction

- Performance of the system

- Structure and function of the system

- Plant chamber

- Temperature control of the plant chamber atmosphere via two cooling towers

- Concepts investigated for temperature control of the plant chamber atmosphere

- First cooling concept: Cooling via the plant chamber ceiling

- Preparation of supply air

- Humidification

- CO2 addition

- Air pressure control

- Irrigation

- Plant lighting

- Lysimeter system

- Gas sampling of lysimeters

- Gas sampling plant chambers

- Evaluation of the control quality and measurement accuracy of an experiment with forage peas

- Control system of AgraSim

- Assembly of the experiment

- Maintenance

- Summary

- Outlook

- Author contributions

- Competing interests

- Disclaimer

- Acknowledgements

- Financial support

- Review statement

- References

- Supplement