the Creative Commons Attribution 4.0 License.

the Creative Commons Attribution 4.0 License.

Towards ice core sampling by subsea robotic vehicles

Christian Katlein

Ice coring has developed into one of the most frequently used sampling methods across cryospheric sciences. Sea ice, firn and glacial ice are sampled using a range of different coring systems. These systems can retrieve core samples with lengths ranging from several cm to tens of meters when operated by hand or drilling machines, while specialized coring systems have retrieved cores from Antarctica's ice caps with a length of over 3 km. In the last decade more robotic subsea vehicles like remotely operated vehicles (ROV) and autonomous underwater vehicles (AUV) have ventured into polar waters beneath sea ice and ice shelves, but retrieval of ice samples from the sub-ice environment has not been achieved on a regular basis. Other geophysical investigation methods such as push core sediment coring and rock drilling have been successfully adapted for subsea robotic vehicles. Hence the purpose of this work is to investigate the feasibility of adapting the techniques of retrieving short ice cores from sea ice and glacial research to the subsea environment. We successfully demonstrate the retrieval of an ice sample in a laboratory setting using traditional ice coring systems in conjunction with a subsea manipulator arm. We discuss challenges and further improvements to our experiments towards enabling reliable ice sampling in the subsea environment using generic tooling readily available on subsea vehicles. In conclusion, ice core sampling in the subsea environment seems feasible using industrial work class manipulators particularly when cartesian inverse-kinematic control is available.

- Article

(1313 KB) - Full-text XML

- BibTeX

- EndNote

Obtaining ice samples from frozen water ice is an important sampling method for cryospheric science. Ice core samples allow for investigations of the physical, biological and chemical properties of sea ice as well as glacial ice and firn. The retrieved samples allow for a diverse set of analyses, that require melting or other processing such as sectioning, which would not be possible in situ. Hence ice coring has developed as a central method throughout all cryospheric sciences. Deep holes have been drilled to retrieve ice cores of several hundred meter lengths from polar ice sheets and glacier caps using highly advanced drilling systems. Shorter core-samples are most often retrieved either by handheld ice coring systems or using regular power tools (Rand and Mellor, 1985). A complete review of different existing coring technologies is available in Talalay (2016); Talalay and Hong (2021).

Obtaining ice samples by drilling from earth's surface is a common procedure. Ice sampling from the subsea environment is however less common. Samples from the underside of ice are of crucial importance, particularly as they enable the analysis of physical processes and properties of the biological habitat at the ice-ocean interface. Examples are the analysis of sea-ice-bottom samples for biological parameters, such as chlorophyll content (e.g. Campbell et al., 2022), or the interest in the microstructure of glacial ice near the bottom (Faria et al., 2014; Moore et al., 1994), just to mention a few. In the case of glacial ice, it is particularly attractive to recover ice samples from the underside of ice-shelves without first drilling through the entire ice column. In addition, sampling by robotic subsea vehicle will also allow for some degree of assessment of spatial variability.

Scientific interest in sampling the sub-ice environment particularly under sea-ice was already raised in the late 1980ies, when a subice suction corer was operated on an articulated arm as well as by a diver underneath sea ice (Welch et al., 1988). This device however only used a suction pump to collect cuttings chipped from the ice by a rotary drill bit and did not retrieve an actual ice core. Since then, subsea robotic technologies have evolved significantly, but no further attempts of retrieving ice samples from underneath the ice are known to the author except from some concept sketches (Vedachalam et al., 2015). Two studies (Vedachalam et al., 2017; Yang, 2019) have investigated thermal ice coring drills for remotely operated vehicle (ROV) or underwater glider deployments. These works however focus on numerical simulation of the coring process and present laboratory tests. From a practical standpoint however, these thermal methods require a lot of electrical power >1000 W and are quite slow in retrieving an ice core. Hence thermal drilling methods do not seem to provide the ease of use to be easily integrated in routine subsea operations underneath polar ice. Different methods of Robotic drilling of ice and rock in extraterrestrial planetary science have also been developed (e.g. Zacny et al., 2023, 2018), but these do not consider drilling from the underside of the ice and are extremely specialized to the individual scope of the respective space mission.

As existing sea-ice ice-coring systems are readily available and provide easy handheld retrieval of short ice cores, this work aims to investigate the applicability of standard ice coring systems for retrieval of short ice-samples from subsea robotic platforms. Subsea use of existing coring systems is characterized along with the capabilities of current subsea robotic manipulator arms. Specialized drilling tools could certainly be constructed, but a method building on existing subsea vehicle components will enable more widespread use.

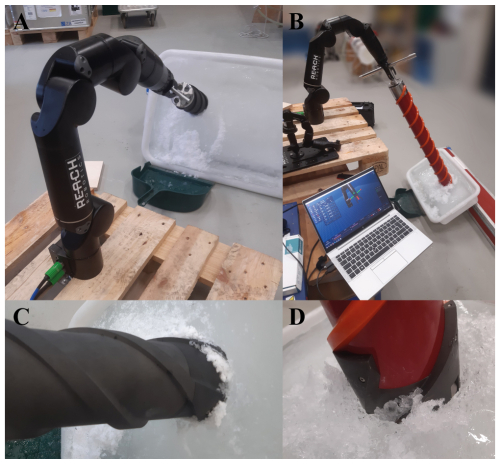

Figure 1Experimental ice drilling setup. The manipulator arm is mounted to a wooden pallet for both coring systems. (a) and (c) show the self-constructed short ice corer, while (b) and (d) show the setup using the commercially available Kovacs Mark II coring system. (b) shows the control laptop running the “Reach Control” software as well as the pendant master arm controller just in front of the manipulator arm.

2.1 Ice coring systems

For the trials two different coring systems were used: One of them was built in-house based on an open-source design, while the second coring system is a commercially available one (Fig. 1).

A small ice corer of a size comparable to a typical sediment push corer was built by the AWI workshop. This form factor could easily be incorporated into under-ice robotic sampling strategies. It was based on an open-source design (Thomsen et al., 2020) provided by the University of Aarhus (Denmark) which was initially developed for robotic ice-sampling as payload underneath an aerial drone (Carlson et al., 2019). The corer has a length of 19 cm and retrieves a core with just under 7 cm diameter. The coring bit consists of three cutting teeth which have a staggered design, so that each cutting tooth is only cutting one third of the slot. The corer is designed to be used on a regular battery powered drill and provides a hexagonal shaft interface for the drill chuck.

The second corer was a Mark II Coring System (Kovacs Ice drilling equipment, Alaska, USA, https://kovacsicedrillingequipment.com/product-category/coring-products/coring-systems/, last access: 5 September 2025). This coring system is widely used in the cryospheric science community and provides an ice core of up to 100 cm in length and 9 cm in diameter. The cutting head consists of two identical cutting teeth and the corer is designed to be both operated by a power drill or using the supplied T-handle for manual coring. The significant length is not optimal for efficient subsea operation, but the manufacturer confirms, that a shorter version can be easily manufactured for subsea operations. The system is also available in versions retrieving a 7.5 and 14 cm diameter core.

In typical field operations both coring systems would be operated using the same handheld cordless power drill, hence in a similar range of rotation rate, torque and drill thrust. However the Mark II coring system is also designed for manual operation at lower rotation rate (revolutions per minute: rpm) and higher torque. Both systems were interfaced to the manipulator arm using a T-handle, a common interface in scientific subsea manipulations. While the T-handle included in the system for manual coring was used for the Mark II corer, a T-handle was improvised for the hexagonal interface on the smaller corer using parts from a ratchet toolbox.

2.2 Subsea manipulator arm

For these trials we did not use a specialized electric or hydraulic subsea drill, but the rotary function of a standard subsea manipulator wrist joint. While this is not designed for drilling, it is designed to replace a human hand under water and hence should be able to operate ice corers designed for manual operation. It highly depends on the situation, but a hand driven standard coring system can reach around 20–25 rpm, while torques as around as 25–200 Nm can be generated by a human operator (Maleki-Ghahfarokhi et al., 2023) on driving the coring system with a T-Handle. These torque and rpm values can be delivered by existing subsea manipulators (see Table 1). If standard vehicle parts can be used in contrast to additional drills it would enable a much easier integration of ice core sampling on existing remotely operated vehicles.

The manipulator was a Bravo 7 Pro (Reach Robotics, Sydney, Australia) 7 function manipulator arm. While the arm provides a depth rating of 450 m water depth, we performed our tests in air for easier observation. The Bravo 7 is one of the most powerful electric subsea manipulators with a lift capacity of 10 kg at full reach and a weight of 9.5 kg. A particular feature of this manipulator arm is the advanced inverse kinematic control that allows control of the end-effector in cartesian coordinate space. This is particularly well suited to allow for exactly aligned drilling motions in axis with the coring device. The manipulator was equipped with an end effector consisting of 4 interlocking jaws that was used to reliably grab the T-handles on both corers. The arm can be controlled by a pendant master arm for manual operation, but drilling trials were performed using the “Reach Control” software in conjunction with keyboard control of the motion in cartesian space. This essentially enabled ice coring to be a two button operation, where one key controlled corer thrust in the axis of the corer and one key controlled the rotary motion of the wrist joint. According to the specification sheet, the wrist joint provides a torque of 20 Nm and a rotational speed of 7.5 rpm. Torque on all motor axes is monitored and can be limited during operation.

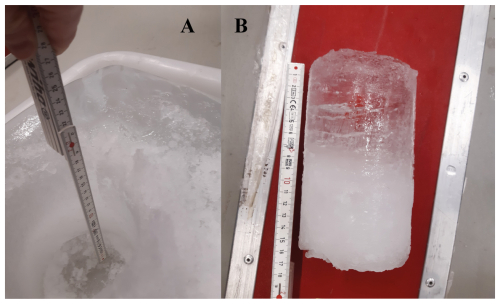

Ice coring tests were performed with a sample tray of tap water frozen into a solid ice block at approximately −15 °C. This ice provides similar mechanical properties to dense glacial ice and is much harder than typical sea ice. Hence this ice provides an upper bound on drilling feasibility, as sea-ice or glacial ice at the sub-ice-water interface will always be softer due to its temperature close to its melting point. When drilling short samples from the sub-ice interface, no influence of fresh meltwater on the drilling process – as occurs when drilling from the surface – is expected. The ice block was taken out of refrigeration shortly before each coring trial, but no efforts were undertaken to conserve the temperature of the ice with visible signs of melting during the experiment.

First tests were performed using the in-house built corer (Fig. 1a and c). However several problems arose with this system: The staggered cutting teeth did not protrude the corer enough to evenly penetrate an uneven surface, leading to strong wobbling of the corer on the ice surface. The hole could not be started using the manipulator due to the low rpm. Only after the hole was started using a cordless power drill the manipulator arm could continue coring to a depth of a few cm. However coring progress was very slow and soon the operation had to be ended, after significant damage had occurred to the sensitive cutting teeth rendering the corer dull and unable to progress. No ice core sample could be retrieved in this first test.

The second round of tests was more successful when the Mark II Coring System from Kovacs Ice Drilling was used. Starting the coring was also difficult, as the corer length made it somewhat too big for easy handling with the Bravo 7 manipulator, and because the larger diameter T-handle provided by the coring system did not provide a stiff enough connection between corer and manipulator end effector. Nevertheless, after some tries the hole was started successfully and the corer did cut the ice. In several occasions the more aggressive cutting teeth of this system cut too deep into the ice leading to torque values too high for the manipulator wrist joint. Rotating the corer counterclockwise to re-engage the cutting teeth in a different position was able to overcome these points where the corer had become stuck. This problem can be avoided by reducing the “cutting pitch” – the protrusion of the cutting teeth from the coring head – by utilizing the so called “elevating screws” to keep the coring head further away from the cutting front and hence limit drilling torque (Rand and Mellor, 1985).

When rotating, the corer proceeded into the ice with a speed comparable to that of manual ice core sampling. Due to the comparably slow rotational speed of the manipulator wrist joint and the corer getting stuck several times, retrieval of the 17 cm long core was achieved within approximately 35 min (Fig. 2). This time can be significantly improved by fine tuning the coring head to the available torque to avoid the corer to get stuck. As this work only aims to investigate the feasibility of subsea ice coring, no further optimization of the drilling process was performed.

As drilling trials were performed in air, excessive heating of the manipulator arm's rotary joint was observed and alleviated by cooling with ice cuttings from the drilling process. Such overheating will likely not occur, when the manipulator is operated submerged in water close to its freezing point and heat can dissipate much more effectively.

The results of these ice coring tests using subsea manipulator arms will be discussed in the following and set into context of the specifications of ROV manipulator arms as frequently used by industrial and scientific ROV teams.

4.1 Challenges

As already reported above, several challenges occurred during the drilling process. The corer got stuck several times as the settings of the coring head lead to higher torque than the manipulator's wrist joint could deliver. This can be both improved by accurately setting the “elevating screws” of the coring head to limit drilling torque, and compensated by using bigger work class manipulators that provide roughly ten times more torque than the Bravo 7 manipulator arm. A higher wrist rotational rate as present on these work class manipulators will also lead to a significantly faster drilling that should be able to achieve rates at least as high as manual driving of the ice coring system. Table 1 provides an overview about the characteristics of frequently used robotic manipulator arms in the work class ROV segment and compares it to values achieved by a human. Typically wrist torques of subsea manipulators range from 8–350 Nm (Sivčev et al., 2018a) at 6–35 rpm. Ice corer torque or cutting force has been investigated in the glaciological community revealing drilling torques of 5–15 Nm (Lv et al., 2024) – a similar order of magnitude.

Starting the coring was challenging at times (see video supplement), but an improved T-handle (or fishtail) interface optimized to snugly fit into the end-effector, as well as a shorter coring system will improve rigidity of the manipulator-corer-system and ease the first phase of coring. A big advantage of using the manipulator arm and not a dedicated coring drill is, that the corer can be disconnected from the arm at any point in the drilling process. Hence it does not pose a threat to vehicle safety if a corer becomes completely stuck even without any additional safety system.

Table 1Specifications of different typical work class manipulator arms in comparison to the model used in this study.

* Cartesian control for the Schilling Robotics manipulators is not commercially available but has been demonstrated in multiple research papers (Sivčev et al., 2018b; Hildebrandt et al., 2008).

4.2 Control of manipulator arm

During our drilling trials, it became apparent, that a key to successful subsea ice core sampling is control of the manipulator's end effector in a cartesian space using inverse kinematics. Due to the comparably long duration of coring operations it is difficult to keep the coring axis unchanged while advancing the corer using a conventional pendant master arm controller. Being able to fix the axis of coring progression and separating the drilling control to two buttons: advancing and rotation enables consistent coring without the risk of additionally introducing high torque due to misalignment of the corer axis. This 6 degree of freedom inverse kinematic control is becoming more common particularly on modern electric manipulators, but also has been implemented within research projects on more traditional hydraulic manipulator arms (Sivčev et al., 2018b; Hildebrandt et al., 2008).

An important consideration to this effect is also the relative positioning of the robotic vehicle during the sample drilling. Relative position keeping underneath ice could be aided by the use of an upward looking Doppler-Velocity-Log (DVL) as input to the vehicle navigation. This technique is very common for seafloor operations and has already been adapted to work above the vehicle (McFarland et al., 2015). Another way to keep the vehicle steady during the drilling operation would consist of spikes on the vehicle in conjunction with thruster action against the ice. Similar techniques are used on the seafloor as well. Generally, stability during drilling operation will be less problematic when using large work class ROV.

4.3 Sample handling and preservation

While these trials covered only the mechanical act of ice core sample retrieval from subsea vehicles, several other issues remain to be tackled for true subsea ice core sampling.

Impact of the sample being completely submerged in seawater will need to be assessed, as well as the possibility to store the retrieved ice corer with sample in some sort of thermally isolated holster, which is also sealed against fluid exchange. The implications will highly depend on the scientific method used to further investigate the ice core sample, but we expect that sufficient scientific value remains. Further investigation is required into how best to retrieve samples after an ROV dive, how long they can be conserved during a dive, and which processing methods must be developed to achieve this.

4.4 Effects of ice properties

The tests have been conducted with a relatively cold freshwater ice block in air. In reality, floating ice will have a temperature close to the temperature of the underlying water, which is either at or above its freezing point. Warmer ice is softer and hence provides less resistance to drilling requiring less torque. As this method only enables the recovery of short ice cores of a maximum length of one ice corer barrel no issues with ductile deformation (creep) of the warm ice are to be expected during drilling. Similarly it is unlikely that water immediately freezes during extraction of the sample complicating corer recovery.

Similarly frozen saltwater, such as sea-ice has even softer mechanical properties (Timco and Weeks, 2010), which further eases ice coring in this robotic approach.

4.5 Future work

While this study has evaluated the feasibility of the approach, a logical next step would need to be real world testing first in a test tank and then using a robotic vehicle in the polar environment. Especially the latter opportunities are still scarce, as there currently are only few deployments of capable robotic vehicles in polar environments. Nevertheless the Author is working actively to further develop the outlined path, particularly as the upcoming generation of polar research icebreakers, such as the newbuild German Polarstern (delivery expected 2030) will be equipped with a suite of capable robotic subsea vehicles specially adapted for the polar regions. Integration of the presented small ice core drill on a small observation class ROV (Katlein et al., 2017) is planned for 2026.

In conclusion our series of trials demonstrates that standard coring systems from the cryospheric sciences can be used for subsea ice core sampling with minor modifications. Current working class manipulator arms provide enough force, torque and rpm for a coring process comparable to manual ice core retrieval and torque values known from glaciological bore-holes. Integration of additional electric or hydraulic drilling tools seems unnecessary, hence making it possible to retrieve ice cores with standard ROV manipulator arms. Easy ice coring requires cartesian inverse kinematic control of the manipulator arm, which is becoming more frequently available on modern work class manipulator systems.

All data is either included in this text or the video Supplement.

A video of drilling experiments can be accessed as electronic supplemental material here: https://doi.org/10.5281/zenodo.13221220 (Katlein, 2024).

The author has declared that there are no competing interests.

Publisher’s note: Copernicus Publications remains neutral with regard to jurisdictional claims made in the text, published maps, institutional affiliations, or any other geographical representation in this paper. While Copernicus Publications makes every effort to include appropriate place names, the final responsibility lies with the authors. Also, please note that this paper has not received English language copy-editing.

This work was funded by the Helmholtz Infrastructure Fund MUSE and the Alfred-Wegener-Institut (AWI). Special thanks to Kathrin Ederer and her team of the mechanical workshop at AWI for manufacturing of the ice corer as well as the team of the AWI-Technikum, in particular Ulrich Knoll, and Anja Batzke from the AWI sea ice physics section for help with the preparation of drilling experiments. We thank Reach Robotics in particular Ethan Grenot for provision of the Bravo Manipulator free of cost for these tests. I acknowledge support by the Open Access publication fund of Alfred-Wegener-Institut Helmholtz-Zentrum für Polar- und Meeresforschung.

This research has been supported by the Alfred-Wegener-Institut Helmholtz-Zentrum für Polar- und Meeresforschung. The drilling trials were supported by the Helmholtz Infrastructure Fund MUSE.

The article processing charges for this open-access publication were covered by the Alfred-Wegener-Institut Helmholtz-Zentrum für Polar- und Meeresforschung.

This paper was edited by David Barclay and reviewed by James Veale and one anonymous referee.

Campbell, K., Matero, I., Bellas, C., Turpin-Jelfs, T., Anhaus, P., Graeve, M., Fripiat, F., Tranter, M., Landy, J. C., Sanchez-Baracaldo, P., Leu, E., Katlein, C., Mundy, C. J., Rysgaard, S., Tedesco, L., Haas, C., and Nicolaus, M.: Monitoring a changing Arctic: Recent advancements in the study of sea ice microbial communities, Ambio, 51, 318–332, https://doi.org/10.1007/s13280-021-01658-z, 2022.

Carlson, D. F., Pasma, J., Jacobsen, M. E., Hansen, M. H., Thomsen, S., Lillethorup, J. P., Tirsgaard, F. S., Flytkjær, A., Melvad, C., Laufer, K., Lund-Hansen, L. C., Meire, L., and Rysgaard, S.: Retrieval of Ice Samples Using the Ice Drone, Frontiers in Earth Science, 7, https://doi.org/10.3389/feart.2019.00287, 2019.

Faria, S. H., Weikusat, I., and Azuma, N.: The microstructure of polar ice. Part I: Highlights from ice core research, Journal of Structural Geology, 61, 2–20, https://doi.org/10.1016/j.jsg.2013.09.010, 2014.

Hildebrandt, M., Albiez, J., and Kirchner, F.: Computer-based control of deep-sea manipulators, OCEANS 2008-MTS/IEEE Kobe Techno-Ocean, 1–6, https://doi.org/10.1109/OCEANSKOBE.2008.4531026, 2008.

Katlein, C.: Towards ice core sampling by subsea robotic vehicles: Electronic supplement – Video from Coring Trials, Zenodo [video], https://doi.org/10.5281/zenodo.13221220, 2024.

Katlein, C., Schiller, M., Belter, H. J., Coppolaro, V., Wenslandt, D., and Nicolaus, M.: A New Remotely Operated Sensor Platform for Interdisciplinary Observations under Sea Ice, Frontiers in Marine Science, 4, https://doi.org/10.3389/fmars.2017.00281, 2017.

Lv, X., Cui, Z., Wang, T., Wen, Y., Liu, A., and Wang, R.: Research into mechanical modeling based on characteristics of the fracture mechanics of ice cutting for scientific drilling in polar regions, The Cryosphere, 18, 3351–3362, https://doi.org/10.5194/tc-18-3351-2024, 2024.

Maleki-Ghahfarokhi, A., Dianat, I., Azghani, M.-r., Asghari-Jafarabadi, M., and Parnianpour, M.: T-shaped handle set-up: effects of handle diameter, between-handle distance, workpiece orientation, working height, and exertion direction on two-handed torque strength, usability, comfort, and discomfort, Ergonomics, 66, 1015–1030, https://doi.org/10.1080/00140139.2022.2122587, 2023.

McFarland, C., Jakuba, M., Suman, S., Kinsey, J., and Whitcomb, L. L.: Toward Ice-Relative Navigation of Underwater Robotic Vehicles Under Moving Sea-Ice: Experimental Evaluation in the Arctic Sea IEEE ICRA 2015, Seattle WA, https://doi.org/10.1109/ICRA.2015.7139392, 2015.

Moore, J. C., Reid, A. P., and Kipfstuhl, J.: Microstructure and electrical properties of marine ice and its relationship to meteoric ice and sea ice, Journal of Geophysical Research: Oceans, 99, 5171–5180, https://doi.org/10.1029/93JC02832, 1994.

Rand, J. and Mellor, M.: Ice-coring augers for shallow depth sampling, https://apps.dtic.mil/sti/pdfs/ADA166630.pdf (last access: 18 October 2025), 1985.

Sivčev, S., Coleman, J., Omerdić, E., Dooly, G., and Toal, D.: Underwater manipulators: A review, Ocean Engineering, 163, 431–450, https://doi.org/10.1016/j.oceaneng.2018.06.018, 2018a.

Sivčev, S., Rossi, M., Coleman, J., Dooly, G., Omerdić, E., and Toal, D.: Fully automatic visual servoing control for work-class marine intervention ROVs, Control Engineering Practice, 74, 153–167, https://doi.org/10.1016/j.conengprac.2018.03.005, 2018b.

Talalay, P. G.: Mechanical ice drilling technology, Springer, https://doi.org/10.1007/978-981-10-0560-2, 2016.

Talalay, P. G. and Hong, J.: Perspectives for development of ice drilling technology: continuation of the discussion, Ann. Glaciol., 62, 143–156, https://doi.org/10.1017/aog.2020.81, 2021.

Thomsen, S., Hansen, M. H., Lillethorup, J. P., Tirsgaard, F. S., Flytkjær, A., Melvad, C., Rysgaard, S., and Carlson, D. F.: An affordable and miniature ice coring drill for rapid acquisition of small iceberg samples, HardwareX, 7, e00101, https://doi.org/10.1016/j.ohx.2020.e00101, 2020.

Timco, G. W. and Weeks, W. F.: A review of the engineering properties of sea ice, Cold Reg. Sci. Tech., 60, 107–129, https://doi.org/10.1016/j.coldregions.2009.10.003, 2010.

Vedachalam, N., Ramesh, S., Subramanian, A. N., Sathianarayanan, D., Ramesh, R., Harikrishnan, G., Pranesh, S. B., Prakash, V. D., Jyothi, V. B. N., Chowdhury, T., Ramadass, G. A., and Atmanand, M. A.: Design and development of Remotely Operated Vehicle for shallow waters and polar research, 2015 IEEE Underwater Technology (UT), 23–25 February 2015, 1–5, https://doi.org/10.1109/UT.2015.7108319, 2015.

Vedachalam, N., Vadivelan, A., Umapathy, A., Murugesan, M., Durai, G., Chandrasekaran, E., Jothi, C., Ramesh, R., Ramesh, S., and Ramadass, G. A.: Concept and testing of a remotely operated vehicle-mountable inductive electrothermal polar under-ice corer, Marine Technology Society Journal, 51, 33–43, 2017.

Welch, H. E., Bergmann, M. A., Jorgenson, J. K., and Burton, W.: A subice suction corer for sampling epontic ice algae, Canadian Journal of Fisheries and Aquatic Sciences, 45, 562–568, 1988.

Yang, Y. E. A.: ROV-mountable underwater thermal corer: General concept, The 8th International Ice Drill Symposium, Copenhagen, 30 September 2019, 2019.

Zacny, K., Mueller, J., Costa, T., Cwik, T., Gray, A., Zimmerman, W., Chow, P., Rehnmark, F., and Adams, G.: SLUSH: Europa hybrid deep drill, 2018 IEEE Aerospace Conference, 3–10 March 2018, 1–14, https://doi.org/10.1109/AERO.2018.8396596, 2018.

Zacny, K., Chu, P., Vendiola, V., Creekmore, P., Ng, P., Goldman, S., Seto, E., Bywaters, K., Bailey, E., Zheng, R., Ware, L., Rashedi, A., Beard, P., Chow, P., Dearing, S., Grossman, A., Huddleston, R., Humphrey, K., Jain, A., Lakomski, D., Mank, Z., Paulsen, G., Martinez, S., O'Bannon, T., Parekh, A., Shasho, J., Wang, A., Wilson, J., Xu, H., Quinn, J., Eichenbaum, A., Captain, J., and Kleinhenz, J.: TRIDENT Drill for VIPER and PRIME-1 Missions to the Moon, in: Earth and Space 2022, Proceedings, 465–474, https://doi.org/10.1061/9780784484470.043, 2023.